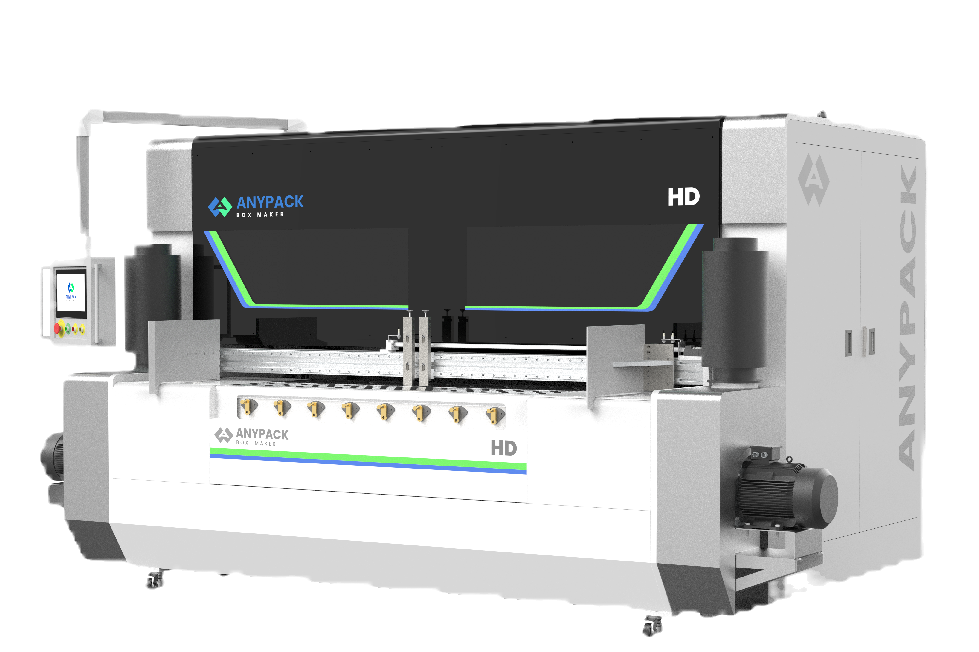

Meet the Next Generation: AB2800HD & AB3000HD

- simon00220

- 1 day ago

- 2 min read

The Ultimate Solution for Heavy-Duty Triple Wall Boxmaking

When it comes to manufacturing large-format, heavy-duty boxes, every second and every square metre counts. Triple wall board can cost upwards of £2.50 per square metre, so the margin for error is razor thin. That’s why our new AnyPack AB2800HD and AB3000HD machines are engineered from the ground up for maximum efficiency, accuracy, and box quality — even on the toughest jobs.

Why Make-Ready Time Matters

For converters and box plants working with premium-grade triple wall corrugated, small runs are the norm. With expensive board and short runs, make-ready time becomes the most critical factor. The first box must be perfect — there’s no room for waste.

This is where the AB2800HD and AB3000HD shine. Thanks to servo-driven set-up, job recall from memory, and automated adjustment systems, these machines can be ready for a new job in as little as 20 seconds. That’s not just fast — it’s industry-leading.

Precision Engineering for Flawless Results

Accuracy is everything when you’re dealing with board up to 16mm thick and weights up to 2,400gsm. Reinforced frames, precision-ground shafts, and upgraded knife assemblies ensure clean cuts and creases every time.

Where other machines crush or tear their way through, the AB2800HD and AB3000HD use specially developed serrated knives to deliver crisp slots and perfect creases — box after box. Customers consistently describe the finished quality as “the best we’ve ever seen.”

Designed for Large Formats and Real-World Handling

Triple wall boxes are big — often 2m wide and up to 6m long. Feeding sheets of this size by hand is neither safe nor efficient. That’s why our machines integrate seamlessly with automatic pallet-to-machine feeding systems.

At the back end, automated stacking solutions keep workflow smooth, even for the largest finished boxes. One operator, full efficiency.

Automation Where It Counts

Short runs mean frequent changeovers. Every minute spent setting up is a minute not producing. The AnyPack HD series automates job recall, knife and scoring adjustment, and even in-line board trimming for oversized stock.

And here’s where the machines go beyond boxmaking:

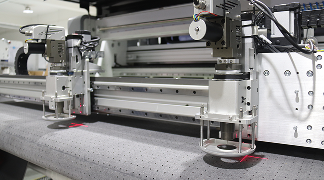

Die-cutting options include vibrating knives for high-speed precision.

Plotter capability means you can produce any box design. Use the boxmaker for perpendicular slots and creases, while the plotter handles curves, bends, tuck-in tabs, hand holes, and complex features.

It’s like having a boxmaker and CAD plotter in one — but with quicker set-up and faster throughput than a standalone plotter.

Specialty features? Drop-down flaps, hand holes, complex die cuts — all handled with power and precision. Our die-cutting units punch cleanly through triple wall, and our halfway-cut capability makes advanced box designs possible without compromise.

The Bottom Line

Few machines in the world can match the AB2800HD and AB3000HD for automation, box quality, and value. Competitors are either less capable, slower to set up, or significantly more expensive.

We believe the HD series is the best value in the market for anyone serious about heavy-duty corrugated boxmaking.

👉 Don’t just take our word for it — request a sample or book a live demo today. See the future of heavy-duty boxmaking for yourself.

Comments